HomeTest Data

Test Data

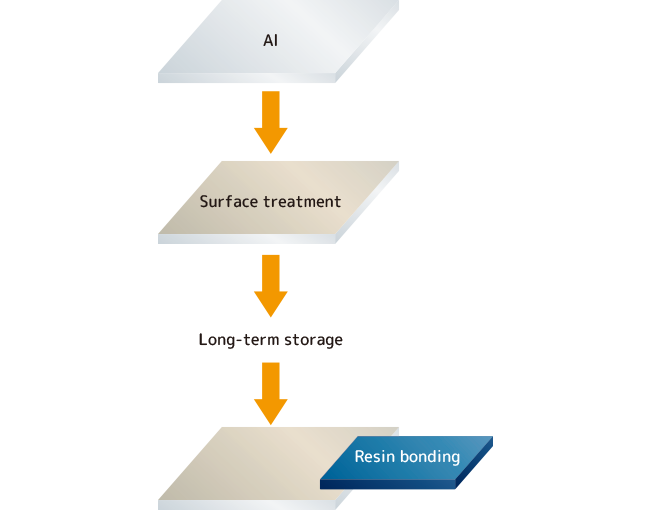

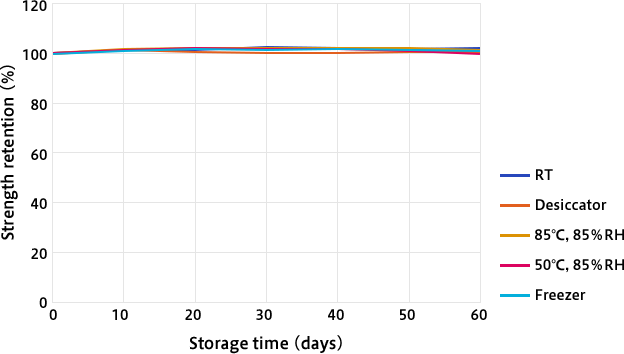

Surface stability of surface treatments for resin bonding

After the surface treatment for bonding, the material was stored in various environments for a predetermined period, and then resin bonding was performed to evaluate the bonding strength.

- Metal:

- A5052

- Surface treatment:

- Laser process

- Resin:

- Aromatic PA

- Storage environment:

- RT, Desiccator (25℃), 85℃, 85%RH, 50℃, 85%RH, Freezer (-18℃)

- Storage time:

- 30days, 60days

Regardless of the storage environment, the fracture mode after the fracture test was a resin base material fracture, and the airtightness was good.

Relationship between storage period and strength retention rate

Relationship between storage period and airtightness

| Environment | 0day | 30days | 60days |

|---|---|---|---|

| RT | 〇 | 〇 | 〇 |

| Desiccator | 〇 | 〇 | 〇 |

| 85℃, 85% | 〇 | 〇 | 〇 |

| 50℃, 85% | 〇 | 〇 | 〇 |

| Freezer | 〇 | 〇 | 〇 |

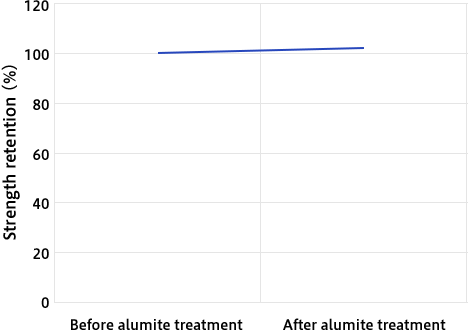

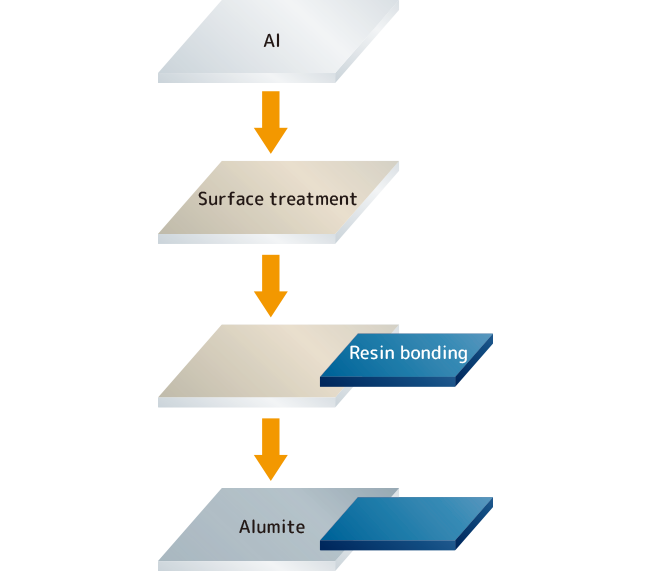

Bonding part alumite resistance test

The alumite resistance of the bonding part was evaluated.

- Metal:

- A5052

- Surface treatment:

- Laser treatment

- Resin:

- Aromatic PA

- Alumite:

- Black alumite treatment

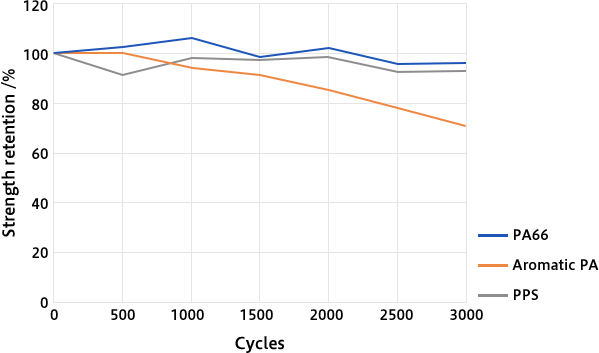

Bonding part reliability test

The heat shock resistance of the bonding part was evaluated.

- Metal:

- A5052

- Surface treatment:

- Laser process

- Resin:

- PA66、Aromatic PA、PPS

- Test condition:

- -40℃ × 30 min ⇔ 125℃ × 30 min

- Test time:

- 3,000cycles

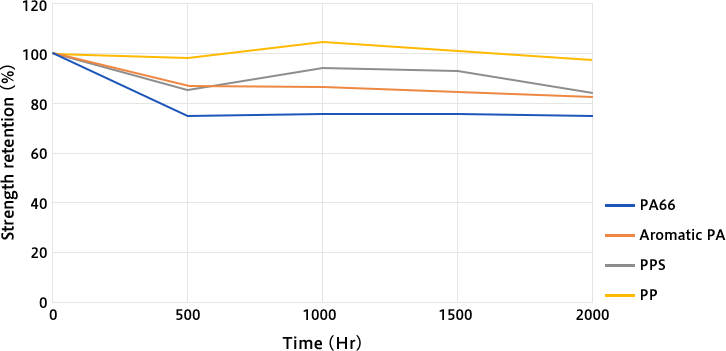

High-temperature and high-humidity resistance evaluation of bonding part

- Metal:

- A5052

- Surface treatment:

- Laser process

- Resin:

- PA66、Aromatic PA、PPS、PP

- Test condition:

- -85℃ × 85%RH

- Test time:

- 2,000 Hours

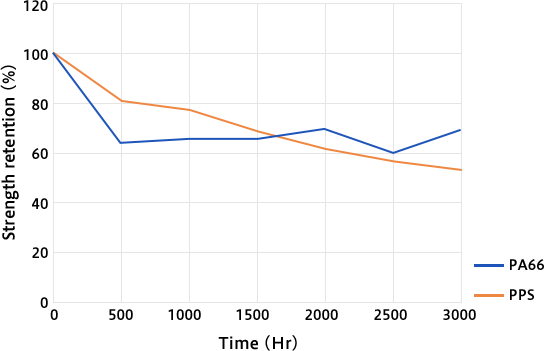

Hot water resistance evaluation of bonding part

- Metal:

- A5052

- Surface treatment:

- Laser treatment

- Resin:

- A66, PPS

- Test condition:

- Immersed in pure water at 70℃

- Test time:

- Up to 3,000 hours

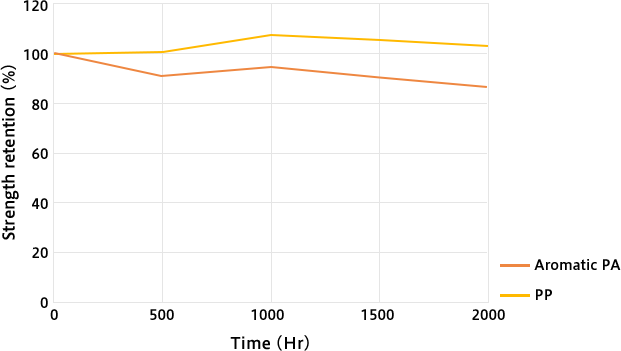

LLC resistance evaluation of bonding part

- Metal:

- A5052

- Surface treatment:

- Laser process

- Resin:

- Aromatic PA, PP

- Test condition:

- The immersion test in 75℃ LLC (Long life coolant)

- Test time:

- 2,000 Hours

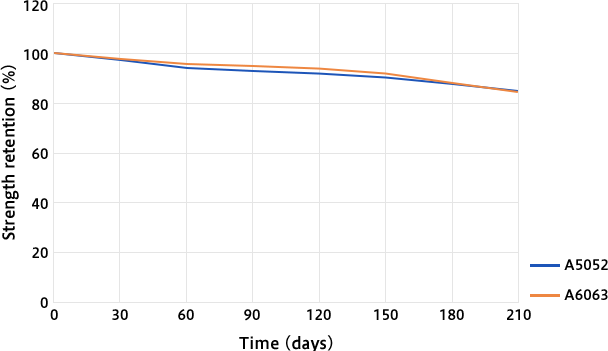

Salt water spray resistance evaluation of bonding part

- Metal:

- A5052, A6063

- Surface treatment:

- Laser process

- Resin:

- Aromatic PA

- Test condition:

- Combinedcyclic corrosion test of repeated salt spray (NaCl), drying, and wetting

- Test time:

- 210days