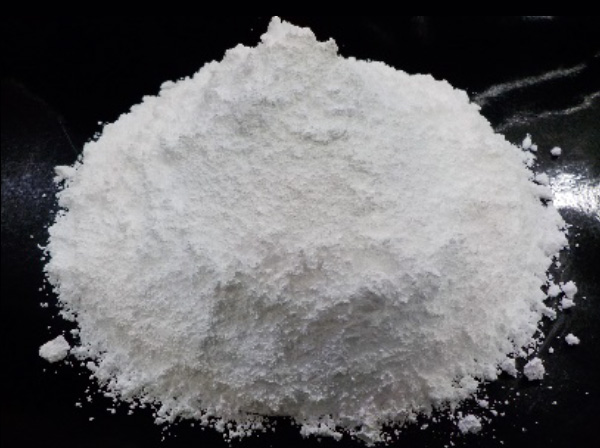

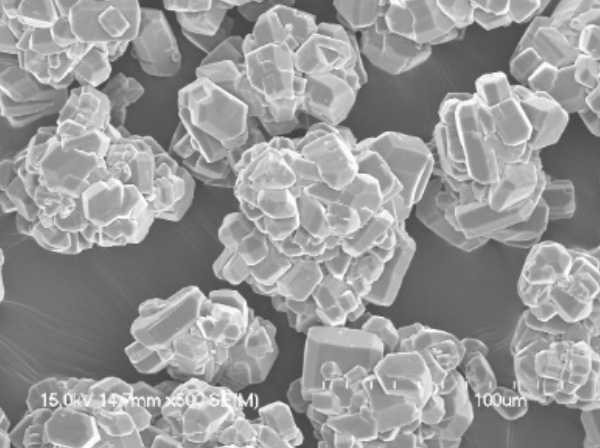

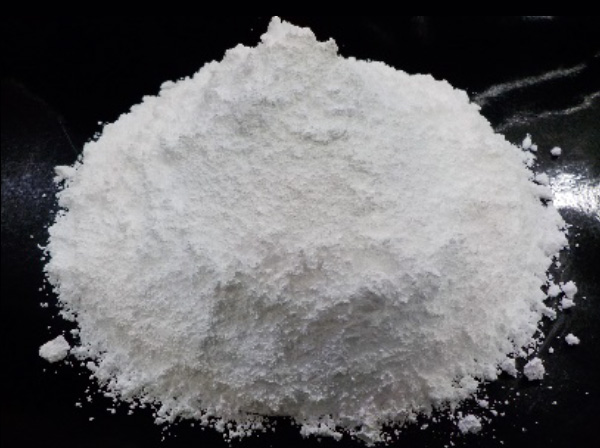

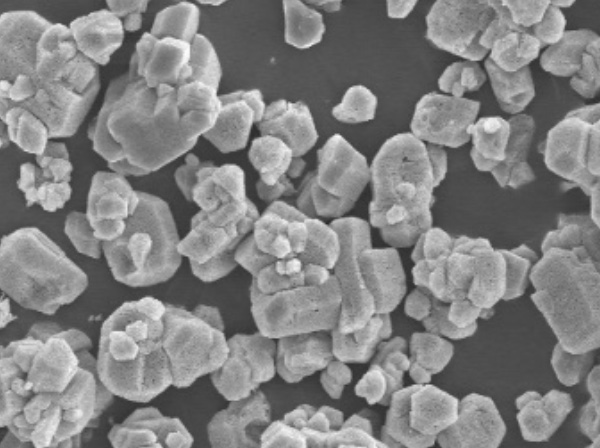

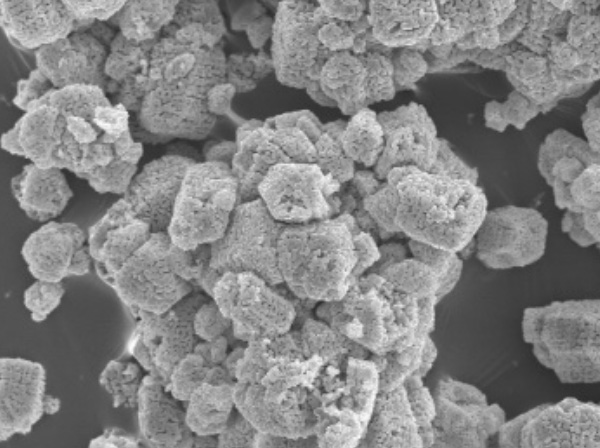

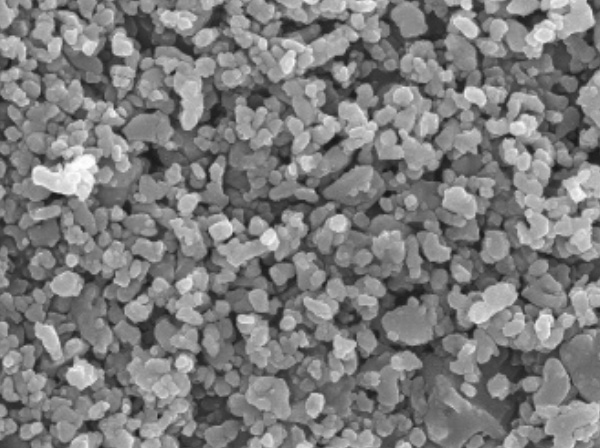

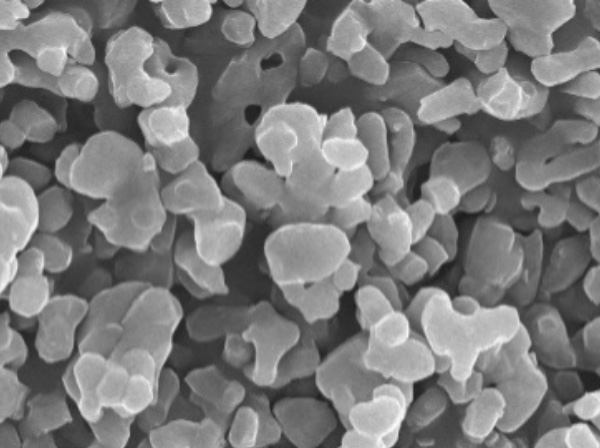

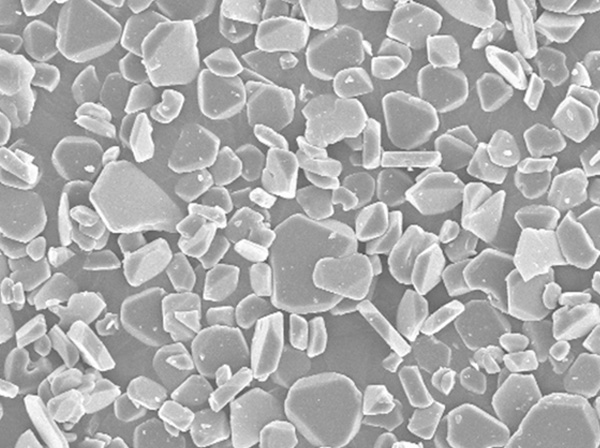

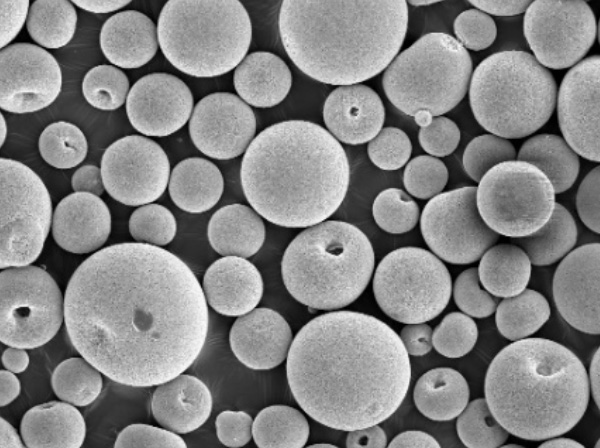

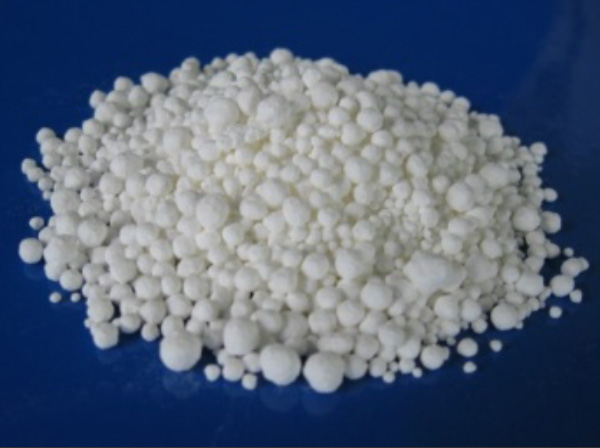

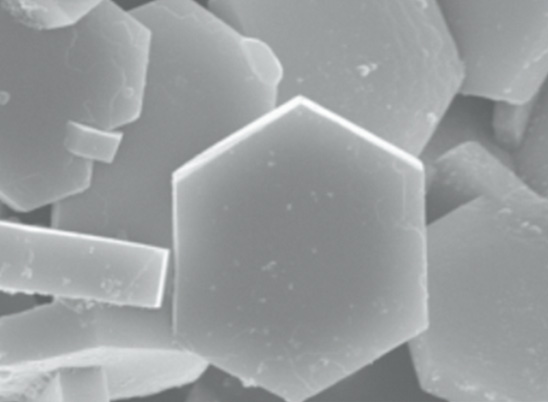

High purity alumina is a white crystalline powder made from high purity aluminum hydroxide and archives high purity with calcination.

Features of high purity alumina are chemical stability, high melting point, high mechanical strength, high hardness, high electrical insulation resistance and good thermal conductivity.

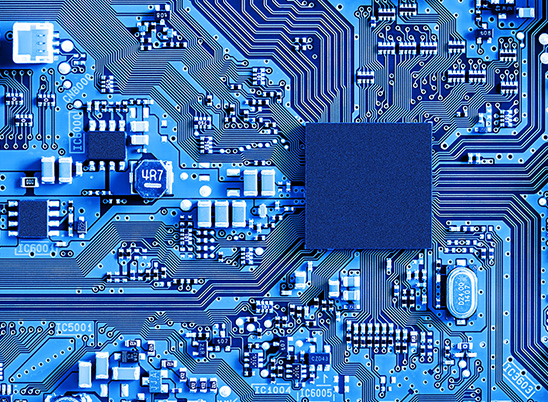

Due to these properties, this product is used in a variety of fields such as ceramics for electronic material and machine parts, resin filler material, raw materials for grinding and polishing, and sapphire raw materials.